Products & Services

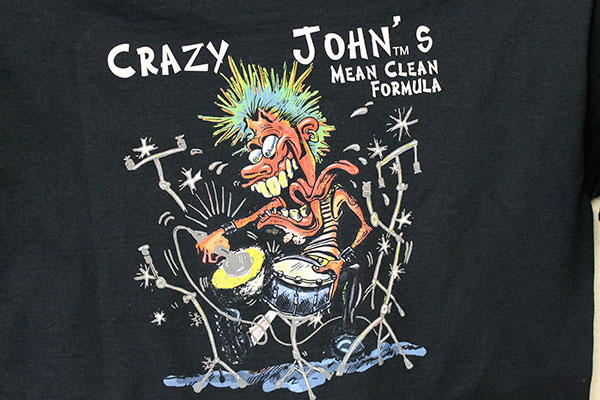

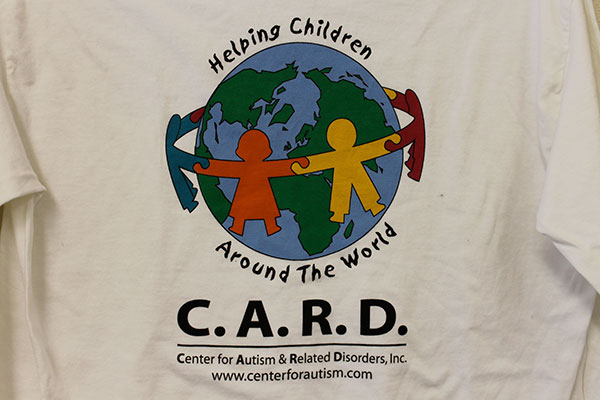

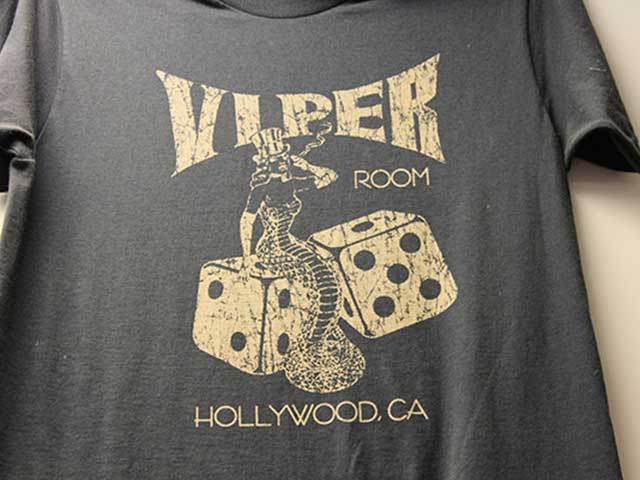

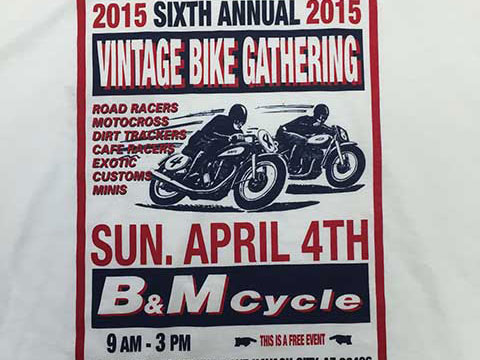

T-Shirts & Embroidery

Below are pictures of T-Shirts and Embroidery projects that we have worked on. Click any image to enlarge it.

Build a T-Shirt Ink Color Chart How it WorksT-Shirts

Embroidery

The Process - How Building a T-Shirt Works

The screen printing process may be more complicated than you might expect. Even in our high tech culture, the screen printing process still requires human decision making and manual labor.

Step 1 - Artwork

First you start with artwork. Screen Tec takes every T-shirt design through Adobe Illustrator. The artwork, once perfected and approved by the customer, is separated by color and printed onto film.

Step 2 - Prepare the Screen

A screen consists of silk screen (actually a synthetic polyester mesh), carefully stretched over a metal or wooden frame. There are many types of mesh screens with different sized openings for more or less ink flow. Each screen must be washed, cleaned, and then covered with a blocking agent.

Step 3 - Put Artwork on the Screen

A critical decision must be made at this point. Based on the artwork, the screen printer must determine which screen mesh count (the size of the opening in the screen) must be selected based on the color in the artwork and the garment type. Some inks are thicker than others and will require a different mesh count. Once the screen is prepared, you can take the film and place it on the screen. The artwork is then "burned" onto the screen.

The "burning" process consists of a light exposure unit and a washing procedure. The direct light on the screen hardens the blocking agent on the screen. The artwork on the film blocks the light, therefore the screen area remains unexposed and can be washed out, providing a controlled area for the ink to flow.

Step 4 - Setup

All colors must be selected to match the artwork and then placed in the screens. The screens must be registered and put in a specific order for the art to look perfect. The screen printer must determine the process based on the blending of colors and drying process.

Step 5 - Screen Print your Shirts

The manual process requires the screen printer to flood (color the screen with ink) and press the ink through the screen with a squeegee. For an automatic screen printing press, once the screens are set up, all that remains is loading and unloading the shirts.

Step 6 - Cure and Fold

Basically all that is left is sending the shirts to the dryer and folding them in dozens. In order for your T-shirt to still look good after the 100th wear, the ink must be fully cured. The temperature of the ink is determined by the time the shirt is under the heater and the temperature of the heater. The heater temperature in a dryer or flash curing unit reaches approximately 800° F, it is possible for the ink film on the garment to reach the full cure temperature of 320° F in approximately 30-40 seconds. Once the ink is cured, it becomes a part of the tee and is ready to wear.

Build a T-Shirt

Ready to get your T-Shirt printed? Need more information? Build a T-Shirt Apparel Catalog Request a Quote